WHAT ARE PLASTIC ADDITIVES? TOP COMMON PLASTIC INDUSTRY ACCESSORIES BEING MOST USED

Developments in the additive formulation world have allowed plastics to take on the role of performing function, rather than simply looking good. Special plastic additives are added to a wide range of color products, giving them special properties.

A good example of an antistatic resin that reduces electrostatic discharge and manages heat. The compounds can even be custom tuned to the needs in the surface resistivity spectrum. This type of plastic can replace metal in certain applications.

What are plastic additives?

Plastic additives are all chemicals used to polymerize, treat, or modify the end-use characteristics of plastics.

Plastic additives are added in a polymer to modify and improve some of its properties. Some of the most common are plasticizers used to lower the glass transition temperature of a polymer (making it softer in some way), fillers to make it cheaper (usually chalk), oil composition to improve its rheology. Others are used for electrical stability reasons or to give polymers a certain capacity (e.g. photovoltaic agents for photolithography).

Of course, the material itself (especially when you add inorganic compounds) is no longer a polymer but a composite with a macromolecular matrix and acts as one.

Most polymers, when synthesized, already contain catalyst residues (sometimes with inorganic aids) and typically they contain a certain minimum amount of heat stabilizer required for hepatization (less than especially in thermoplastics). Other oxidizing and heat stabilizers can be added afterwards and there is a wide range of other compounds such as UV stabilizers, chelators, secondary stabilizers, plasticizers, antistatic additives, an impact modifier that alters the properties of the resin compound. I also agree that polymers that have been filled and recycled with solid heterophase additives should be treated as a separate layer (composites), and these "additives" should be referred to as fillers . However, the borders are not sharp because incompatible mixtures can be considered as organic-filled polymers. Polymer Additives Introductions Thermo plastics materials are processed

What is the most commonly used plastic additive today?

1. Anti-stick additives (anti-block, clumping)

Adhesion can adversely affect machining and film forming applications, sometimes rendering the film unusable. To reduce contact between films and prevent suction, an additive to the film surface is roughened to create a tensile effect, which is a plastic anti-adhesive.

The anti-adhesive plastic additive must be highly effective and exhibit stable and reliable quality, with little or no effect on the film properties, especially LLDPE and LDPE films. , anti-stick agents and anti-slip additives are used together with polymers to create a suitable processing environment for the film.

The main ingredients of plastic anti-stick additives are usually: synthetic silicon dioxide (SiO2) (smoked silicon, silicon gel, zeolite) or natural and mineral SiO2 (clay, diatomite, quartz, talc). Synthetic materials have the advantage of being free of crystallization (chalk dust), while natural materials do. Therefore, when using natural materials, special treatment is required to reduce chalk dust and also a different printing method is required.

In terms of safety, anti-stick additives as well as other plastic additives are harmless to the end consumer, in line with state regulations on food-related products.

Products that are often stuck together: packaging, plastic...

Clumping is a state of adhesion between films that stick together, making it difficult to separate them from each other. The cause of this phenomenon can be due to: affinity for each other, opposite charges, vacuum ...

This phenomenon causes many difficulties in the production process:

- Difficult to open the mouth of the package, which takes time

Makes it difficult to put the product inside the bag, sometimes causing spills...

Slippery Additives or Anti-caking Agents make the surface of the film rough (rough) so that air can easily interfere with the film, eliminating the vacuum effect. In some special cases, an antistatic component is added, thanks to the entry of air, the steam will combine and block the charges on the membrane surface. Thereby eliminating the phenomenon of clumping with charged particles.

The composition of antifreeze can be inorganic or organic:

- Inorganic: Silica, Talc, CaCO3, Alumina silicate, Kaoline, Mica, etc. Depending on the thickness of the film, different inorganic particles are required.

Organic: Ethylene BisSteramide, Stearyl erucamide, Glycerol monostearate, zinc stearate, teflon, ...

Criteria for selection of plastic anti-stick additives:

- Particle size: Affects additive performance and physical properties of the final product.

Surface : Affects the coefficient of friction of the membrane and the degree of wear of the device.

Specific Gravity: Indicates the relative weight of the product.

Density: Affects the quality of the final product.

NS

Common types of plastic non-stick additives:

- Diatomaceous earth

- Talc

- Calcium carbonate (CaCO3)

- Synthesis of silicas and silicates

2. Transparent additive

During processing, a number of factors can reduce the clarity of the product such as fillers, the use of recycled plastic, etc. Therefore, the settling tank is an effective solution to solve the above problem. Solving this problem, both increases the gloss of the product, and helps reduce costs for the manufacturer.

Using only a low percentage to increase grain clarity, quality and potential cost, benefits can be achieved through reduced cycle times and energy savings. With a small amount of insertion, the increase of the plastic additive inside does not adversely affect the welding, gluing or processing properties as well as the adhesion of printing ink, glue ...

Application:

Plastic additives are used and applied in the field of palstic, mainly used in:

- With PP plastic: household products, pp film, profiled film, box tray...

With PE plastic: LLDPE packaging, mesh plastic, household plastic, HDPE foam bag...

3. Filler for plastic: Filler masterbatch

Filler masterbatch (taical) is a calcium carbonate (CaCO3) based filler - a calcium carbonate filler, used in the plastic industry to change the different properties of turpentine or polymer resin, in order to reduce product costs for client. .

Taical - filler masterbatch is processed by melting a mixture of rock - calcium carbonate powder, resin additives and primary resin into a liquid resin, then cooled, cut into small particles. These particles will be mixed with primary plastic and continue to undergo processing processes such as blowing film, spinning, injection molding ... to create plastic products.

Application:

Area of plastic additives applied in those fields:

Reduce costs in the production of film, plastic packaging, shopping bags and PE bags.

Producing ceiling panels, frames, plastic doors.

Producing PVC pipes and plastic accessories, electric cables.

Application in molding, injection molding of other plastic products...

4. PP . hardening additive

In the process of processing PP plastic, depending on the type of plastic and the properties of the product, the plastic affects the shrinkage, the product is often warped, uneven in shape, etc., causing difficulties in the processing process. assembly and use. There can be many reasons, typically due to the limited cooling stage, which does not help the product to form quickly.

The hardener will help the product to shape quickly, making the product more transparent, not warping or deforming. Not only that, the hardener also helps to reduce the pressing cycle, thereby increasing production efficiency, helping to reduce costs.

5. Anti-UV plastic additives

When exposed to sunlight or some other artificial light, UV rays can break the bonds in polymers. This is a photochemical degradation process and is the main cause of bond breakage, chalking, color change and deterioration of physical properties of polymers.

To combat UV damage, one solution is to use a free radical scavenger - Hindering Amine Light Stabilizer (HALS). HALS is extremely effective against light attenuation for most polymers. They do not absorb UV but work by reacting with free radicals (which cause polymer breakdown). Thereby helping plastic products retain their mechanical properties, prolonging the use time of plastic products. With very little HALS content, significant effects can be achieved.

6. Anti-static plastic additives

During processing, the plastic particles are constantly rubbing against each other, forming an electrostatic attraction. This leads to a certain amount of dust on the plastic surface, reducing the transparency as well as the aesthetics of the product.

Antistatic resin additives are created to bond between the base resin and the antistatic component, which reduces the ability to charge on the surface of the film, making production safer and more efficient. At the same time, minimize the situation of vacuuming and dusting on products when displaying and storing.

There are 2 types of antistatic plastic additives:

- Anti-static unstable: including surface desiccant, organic salt, glycol, polyethylene glycol..

Long-lasting antistatic: polyhydroxypolyamines (PHPA), polyalkylene and polyacrylic copolymers.

Application:

Anti-static plastic additive is used to reduce static electricity for PE, PP ... in the fields of:

- Film blown film

Injection molding, tube extrusion, bottle blowing.

7. Flame retardant plastic additives

Most plastics are highly flammable due to their carbon chain molecular structure. Therefore, to improve the fire resistance of this material, people use flame retardant additives with the following mechanism:

- Create a protective layer on the surface of the solid phase (primary layer)

Free radical quenching works on the gas phase

Some common flame retardant additives:

- Flame retardant halogen: contains halogen polymers

DOPO derivatives: polyphenolic hydroxyl/amine derivatives, ammonium polyphosphate, melamine phosphate...

Inorganic flame retardants: Aluminum hydroxide [Al(OH) 3], Magnesium hydroxide [Mg(OH) 2], Red phosphorus, expanded graphite, Ammonium polyphosphate (APP)...

Organic flame retardants: N - diamino - benzene (2 - hydroxy) 4 dibenzyl ester acid; dimethyl methylphosphate (DMMP).

8. Anti-fog plastic additive

The term "fog" is used to describe the condensation of water vapor on a plastic film in the form of small, individual water droplets. Frostbite occurs when air masses with water vapor are enclosed and cooled to a temperature below condensation. Water vapor condensation is commonly observed when food in plastic packaging is stored in refrigerators and in greenhouses. To overcome this phenomenon, antirust agents are researched and developed.

Anti-fog agents, also known as anti-fog agents, are chemical substances that prevent the condensation of water in the form of droplets on that surface such as fog. Common anti-fog additives:

- PLA: is a aliphatic polyester similar to PET in terms of surface energy and polar properties compared to olefins.

Lanxess AF DP1-1701: Anti-fog and anti-condensation coating system used for rigid panels, multiwall panels, corrugated board and other finished products made from polycarbonate, source injection molding products from the same material. ..

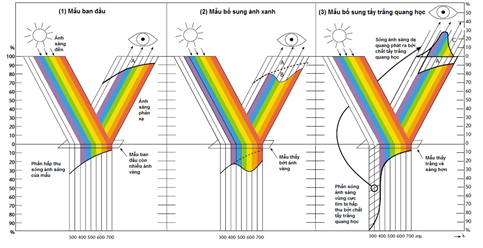

9. Optical bleaching additive

Optical bleach (commonly referred to as "super bleach") is a relatively commonly used ingredient in the plastics industry. They have a high ability to absorb ultraviolet and ultraviolet light, converting the absorbed light energy into visible light waves that range in color from blue to violet. They emit light, so they are also called luminescents.

The use of optical bleaches significantly improves the appearance and color of the product because:

- Helps the product to be less discolored (especially when the product uses scrap)

Make colors brighter, more vibrant.

Some of today's fluorescent cleaners:

- OB-1: suitable for whitening polyester, nylon, poly propylene, PVC, ABS, EVA, polystyrene...

OB: odorless, light green powder, soluble in most organic solvents such as alkanes, fats, mineral oils, paraffins.

KCB: Kelly powder is light in color, non-toxic, odorless and insoluble in water, heat resistant.

KSB: light colored powder, non-toxic, odorless, insoluble in water, but soluble in most organic solvents.

FP (127): high whiteness, beautiful color, high heat resistance and corrosion resistance, soluble in organic solvents, good compatibility with PVC and polystyrene.

DBH: has strong fluorescence intensity, high whiteness, heat resistant at 330C

KSN: good compatibility with plastic, high temperature strength and good corrosion resistance, suitable for whitening polyester and plastic.

KB: Strong fluorescence intensity and high whiteness, heat resistance.

10. Biodegradable plastic additives

The complete decomposition of plastic will take a long time, which is an alarming environmental problem today. A decomposition additive controls the breakdown and turns the plastic at the end of the cycle into a material with a completely different molecular structure. This structure is capable of breaking down into simple molecules such as: CO2, H2O, CH4, inorganic compounds or biomass...

Currently on the market there are many additives to support biodegradation in plastic production. They are mostly synthesized from environmentally friendly organic substances. Reverte additives stand out among these. Reverte has the function of turning non-biodegradable products such as plastic bags or nylon bags into an object with biodegradable properties like a natural entity (similar to leaves, animals and plants... ). Reverte's main task is to continuously shorten the polyolefin molecular chain, under the influence of oxygen, sunlight and temperature.

11. Additives to increase porosity for plastic products

Foaming additive is a method of creating pores inside plastic products that manufacturers use to reduce the volume, reduce the amount of plastic produced while still ensuring product quality. The output product will have improved thermal and sound insulation properties, increase the durability of the plastic structure, and minimize shrinkage and protrusion on the plastic surface.

There are two types of foam additives for plastics based on the type of foaming agent:

Physical foaming agent: compressed air nitrogen, liquid CO2 as short-chain aliphatic hydrocarbons

Chemical foaming agents: azodicabonamide (ADC), azisobutylric, benzene, sullfonyl hydazide.

12. Plastic deodorant additive

The application of plastic deodorant additives is increasingly popular, widespread and related to people's daily lives. For example, children's toys, household products, food bags, stationery, plastic pipe materials etc. in many cases plastic products are not only made from plastic materials but also added into additives in certain doses or small amounts of recycled materials, although it is still mainly plastic materials.

The cause of adding additives and recycled materials has caused plastic products to contain odors such as C2H4, H2S, SO2, AMIN, NH3. Some of the odor may be released over time but there is still some odor remaining in the product even though the product is used for a long time and is affected by external temperature, the odor will released, affecting the environment and humans.

13. Anti-aging additives for plastic products

Anti-aging additives have the ability to widen the limited temperature range for plastics, increasing the life of the plastic many times so that the use time is longer. This additive works by slowing the development of a reaction caused by oxygen or peroxide.

Anti-aging fillers use materials that are two types of anti-aging agents including Phenonic, Amine, a mixture of sulfur or phosphorus.

14. slip additive

The principle of operation of the lubricant in the polymer blend is a highly mobile component with a low coefficient of sliding friction. In the machined condition, they act as a flexible buffer between the molecules and between the polymer and the device wall.

Smoothing agents are usually substances with low molecular size, low coefficient of friction, and their melting point is also low. They easily migrate to the outer surface of the product immediately after machining and form a favorable gliding cushion on the surface of the product, so that the product slides smoothly on the contact surfaces.

15. Stability Additives

Plastic additives help increase the stability of plastic products during the production process. Including heat stabilizers, UV stabilizers, etc.

Heat stabilizer additive mainly used for hard and soft PVC plastic, works to ensure the plastic is stable, does not decompose when processed at melting temperature. To create thermally stable additive masterbatch, we can use organic substances such as salt, cadmium, calcium, zinc, etc.

UV stabilizer additives, also known as anti-UV additives, use hydroxybenzo, esters of Acrylic acid, hydroxyphenyl, benztriazoles, etc. to protect plastics when they are exposed to sunlight outdoors for a long time. .

Above are the Top 15 popular plastic additives in the plastic industry that Sunrise Colors Vietnam Company would like to introduce to readers. And our plastic additive company is also directly supplying the above plastic additives, to learn more about the quality products of our business, we invite you to refer to the product catalog "Industry additives". plastic ".

SUNRISE COLOURS VIETNAM CO., LTD

Add: CT2A Building, Gelexia Riverside Apartment, 885 Tam Trinh Street, Yen So Ward, Hoang Mai District, Hanoi City.

Phone: +84 986998350 Fax: 0084 02436452586

Moblie/What'sapp/Wechat: 84 986998350

Email: sales3@sunrisecolour.com

Website: http://sunrisecolour.com

Related posts

.png)